BP-D5

This special-use surface tensiometer measures dynamic surface tension of surfactant solutions, using the maximum bubble pressure method.

Features

- Lifetime can be changed automatically to draw variations over time in a single process.

- Realtime display of the bubble pressure waveform for monitoring of bub ble generation.

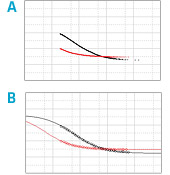

- Real time graphing of the measurement result. (A)

- Applies Rosen fitting to the measured results and presents the maximum slope of graph. (B)

- Draws up to 11 data samples on a single sheet for comparison.

Applications

- Surfactant: Study of the fundamental property

- Ink, Coating agents: instantaneous wettability

- Fountain solutions in offset printing: adsorbing speed of the surfactant

- Aerosol, Emulsion: instantaneous generation of small droplets

- Detergent, Extinguishant: Initial foaming

Why is dynamic surface tension required?

"Surface tension was low enough, but during the actual coating process, the wetting result was insufficient." Have you ever faced this dilemma?

Coating agents generally include surfactants to control their wettability to materials, by lowering surface tension. The surfactants can adsorb toward the solution surface gradually, changing the surface tension of the solution over time. Thus, for target solutions that include surfactants, surface tension must be studied over time.

The widely-known Wilhelmy plate method and du Nouy ring method measure surface tension under conditions in which the surfactant adsorbtion has equilibrated, called Static Surface Tension. But coating solutions are in constant change, with surfactants continually adsorbing to new surface and bulking up as micelle. In such conditions, the speed at which surface tension drops, via the time function Dynamic Surface Tension, becomes important. The BP-D5 allows measuring Dynamic Surface Tension with its Bubble Pressure technique.

Measurement principle

BP-D5 principle

When pressurized air is blown through a capillary constantly, the pressure inside the capillary changes in a regular cycle (a) ~ (d).

When the curvature radius of bubble R equals the radius of capillary outlet r, the pressure will reach a maximum. (c)

Then, go down. (d)

The bubble pressure method measures the maximum pressure and converts it into surface tension.

The cycle (a) to (c) is Lifetime and quantity of surfactants adsorbed on the bubble surface during this cycle affects surface tension.

The bubble pressure method measures the maximum pressure and converts it into surface tension.

The cycle (a) to (c) is Lifetime and quantity of surfactants adsorbed on the bubble surface during this cycle affects surface tension.